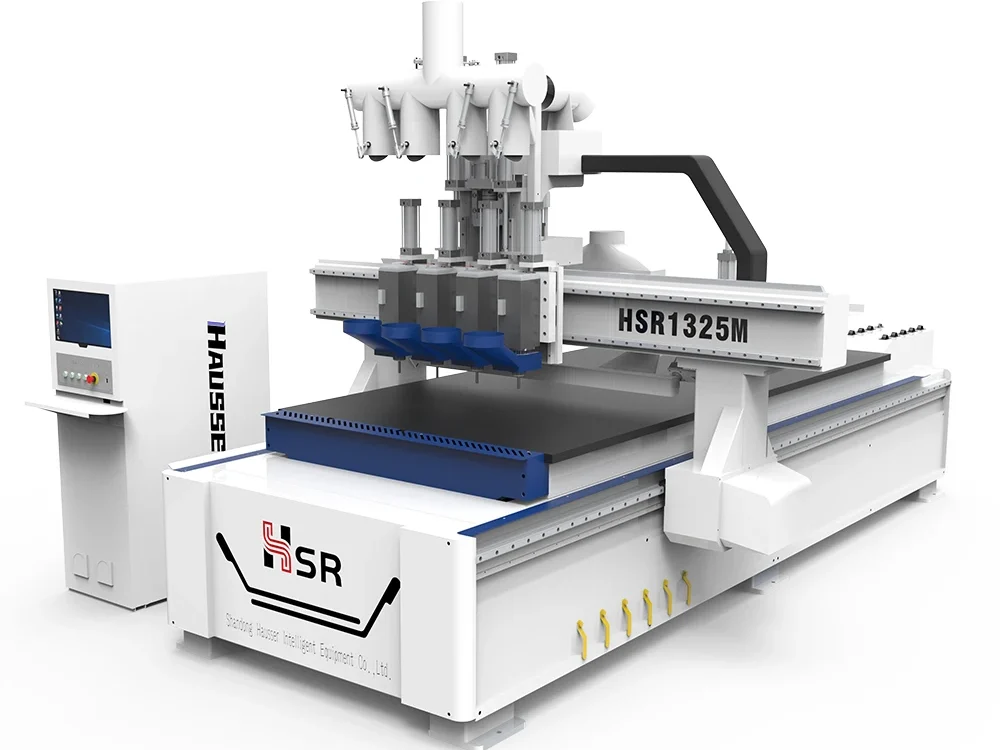

Detailed Description

1) Designed for customized furniture, panel-type furniture, customized closet cabinet production, it has cutting, drilling, grooving and other processing functions, improves efficiency, save material and labor.

2)Simple operation: installed with automatic typesetting software, simply enter sheet size to automatically optimize the layout, workers can easily operating this machine after 3-5 hours training.

3) Machine frame is heat treated after welding to remove any welding stress or tension.

4) Safety light sensor system using three light beams protecting the operator standing at the front of the machine and 1800mm high safety fences at both ends and across the rear of the machine.

CNC Router Parameter

| MODEL | HSR1325R ATC CNC ROUTER |

|---|---|

| Spindle | 9KW ATC air cooling spindle |

| Spindle speed | 0-18000RPM |

| Control System | SYNTEC |

| Inverter | 11KW Folinn inverter |

| Tool magazine | 20 pieces knives |

| Re-positioning accuracy | ±0.03mm |

| Working voltage | (220V 50/60Hz)(380V 50/60Hz) |

CNC Router Video

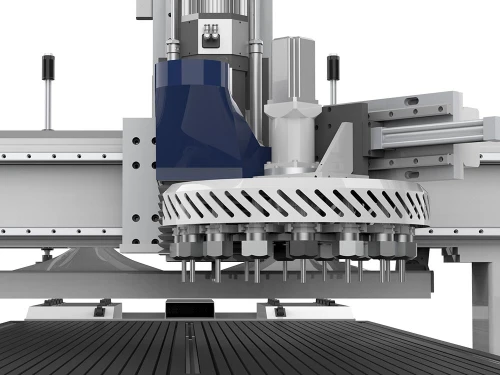

Tool Magazine

Disc tool magazine placed on the side of the gantry knife library can be 12-20, high stability.

It can be made next to the spindle, generally within 14 knives, and the tool change speed is faster.

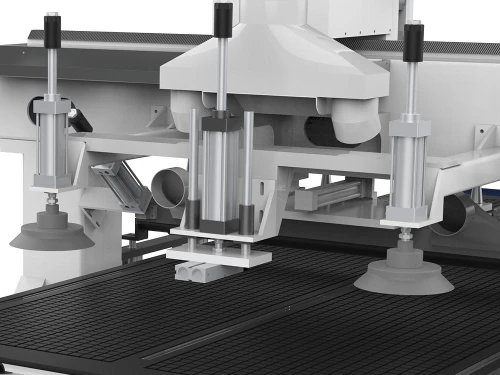

Vacuum table

The vaccum partition can be customized as needed and designed according to the size of the processed product.

Equipped with 7.5kw or 11kw vacuum pump, large adsorption force.

Auto loading system

With the cooperation of the cylinder and roller, this device can automatically feed, saving the time of manual feeding.