Detailed Description

An automatic CNC tool changer has numerous significant benefits in the workshop, including:

Increased accuracy

Increased efficiency

Reduced labor cost

Reduced downtime and total production time

Increased tool storage capacity

Increased machine versatility

Increased safety for employees and equipment

Ability to change larger and heavier tools with ease

Increased edge finish due to more appropriate tooling per process

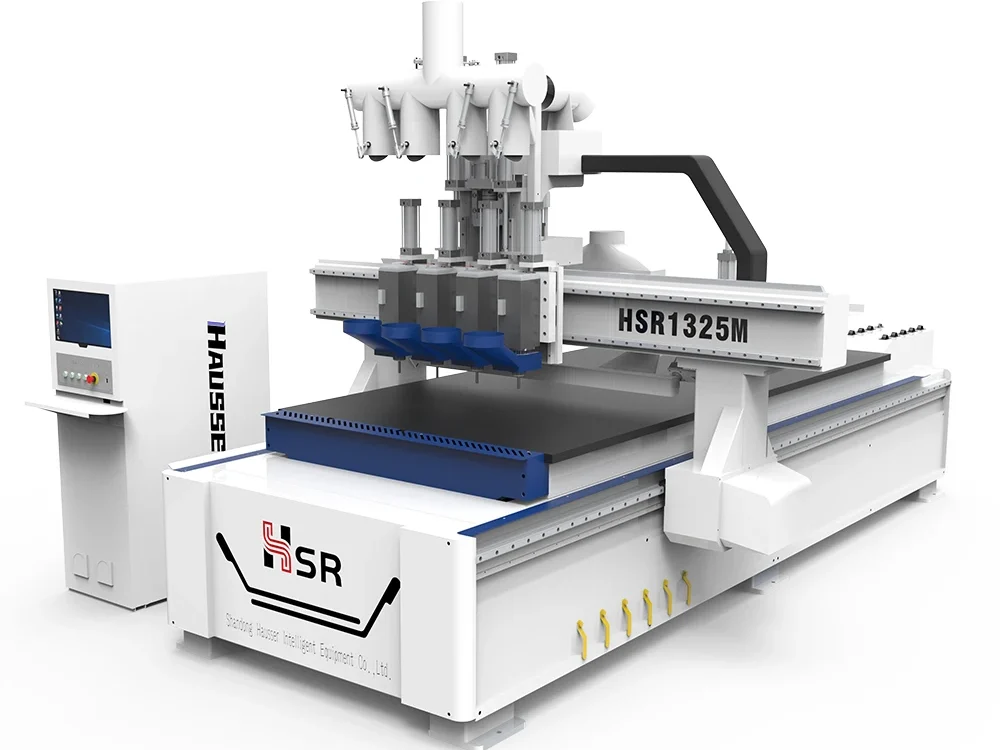

CNC Router Parameter

| MODEL | HSR1325F |

|---|---|

| Spindle | 6kw HQD air cooling spindles with 4 sets or according to user needs |

| Control system | Syntec |

| Motor and drive | Syntec servo motor and driver |

| Reducer | Japan SHIMPO reducer |

| Positioning cylinder | 5 sets |

| Repeated positioning accuracy | ±0.03mm |

| Weight | 3000KG |

CNC Router Video

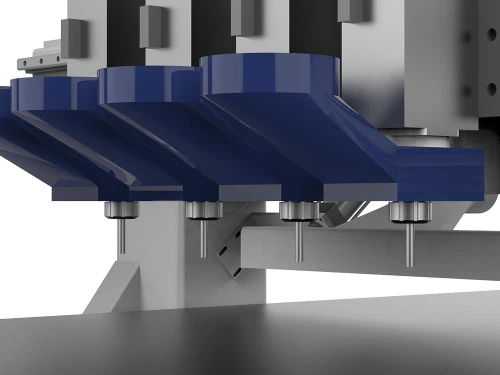

6KW AIR COOLING SPINDLE

Our company is different from other companies, compared with 2*6kw, 2*3.2kw spindle, our company uses 4*6kw air-cooled spindle, not only greatly improve the work efficiency, but also cooperate with the system to greatly reduce the failure rate.

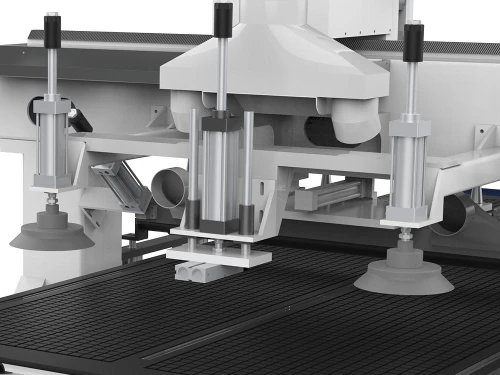

Auto loading system

With the cooperation of the cylinder and roller, this device can automatically feed, saving the time of manual feeding

Auto unloading system

With the help of this device, the processed sheet can be automatically pushed down the table surface at the same time of feeding, and the automatic loading and unloading can be realized.

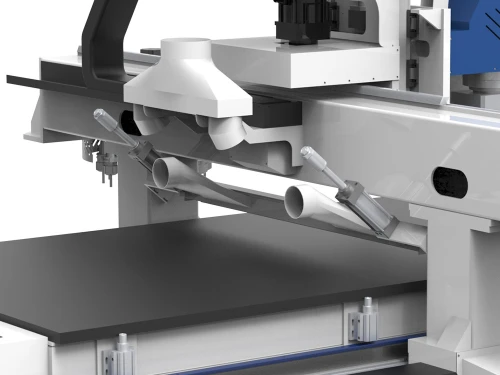

PEK Guide

German PEK guide line, which has stable performance and lower noise while machine is working, service life of more than 100,000 hours.