Detailed Description

The benefit of ATC CNC ROUTER Machine

-

Increased efficiency and productivity: With an ATC CNC router, you do not have to manually change the cutting tools, which saves time and reduces the risk of human error. This allows you to complete more work in less time, resulting in increased efficiency and productivity.

-

Improved accuracy and precision: Automatic tool changes ensure that the cutting tool is properly aligned and calibrated, which results in increased accuracy and precision of cuts.

-

Enhanced versatility: With an ATC CNC router, you can use a variety of cutting tools, which allows you to work with a range of materials and achieve different types of cuts and finishes.

-

Reduced cost: While an ATC CNC router may have a higher initial cost than a manual machine, it can save money in the long term by reducing labor costs and increasing productivity.

-

Reduced risk of injury: Changing cutting tools manually can be dangerous, especially if you are working with sharp tools or heavy machinery. ATC CNC routers eliminate the need for manual tool changes, reducing the risk of injury.

- Add 5+4 drilling group, high drilling efficiency.

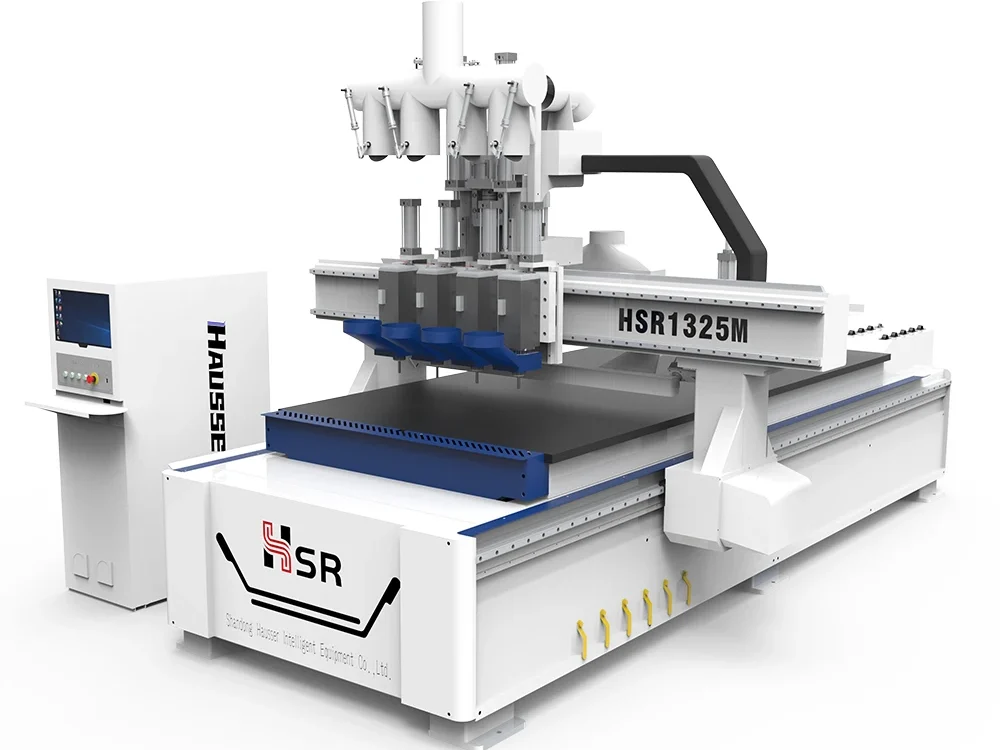

CNC Router Parameter

| MODEL | HSR1325A |

|---|---|

| Control System | SYNTEC |

| Spindle | 9KW ATC air cooling spindle |

| Motor and Driver | Syntec servo motor and driver |

| Inverter | 11KW Folinn inverter |

| Working accuracy | ±0.03mm |

| Software | ArtCam, Ucancam,Type3 |

| Voltage | (220V 50/60Hz)(380V 50/60Hz) |

CNC Router Video

9KW AIR COOLING SPINDLE and 5+4 DRILLING BAG

CC Air cooling spindle, which is stable, durable, and has high precision

5+4 drill bit, one time to make a variety of different holes.

Tool Magazine

Linear tool magazine can be placed under the gantry to move with the gantry, or can be placed on the back end of the machine.

It can hold 14-16 knives and can be customized as needed

Auto loading system

With the cooperation of the cylinder, this device can automatically feed, saving the time of manual feeding