What is ATC CNC Router?

ATC stands for automatic tool changer. An ATC CNC router adopts an electric spindle which automatically loosens or clamps tools by the movement of the internal cylinder. And the electric ATC spindle quickly auto changes the cutting tools without stopping work. An ordinary CNC router only adopts one cutting bit on the spindle. And the operator needs to stop the machine and then manually replaces the tool, which affects the processing efficiency in a negative way. The invention of automatic tool changer CNC router represents the most technological CNC router. It changes tools automatically and greatly saves the processing time and manpower.

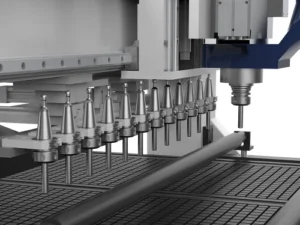

The intelligent tool change function of the machine depends on the control system and tool magazine. The control system controls the movement of gantry and spindle. And the tool magazine carries multiple cutting tools. When a tool completes its machining work, the spindle moves to the tool magazine and releases the tool. Next, it automatically grabs the next tool for subsequent processing. Automatic tool changer function is the final trend of CNC router development. It is the best choice for large and medium-scale processing projects.

There are two types of tool magazines: linear tool magazine and disc tool magazine.

Linear Tool Magazine

Linear tool magazine is a linear device on which there are multiple cutting tools are adopted. This tool magazine can be installed under the gantry or behind the workbench according to user’s requirements. For example, if the user wants to change tools faster, the manufacturer can install the tool magazine under the gantry. If the user wants to leave enough processing area, the tool magazine can be installed behind the workbench. Watch below video to see the working demonstration of ATC CNC router with linear tool magazine.

Disc Tool Magazine

Unlike linear tool magazine, disc tool magazine completes the tool switching through its own rotation. The tools on the tool magazine are installed parallel to the center of the spindle. Disc tool magazine can be installed in different positions according to user’s requirements. And the tool switching process just takes a few seconds. Watch below video to see the working demonstration of ATC CNC router with disc tool magazine.

Both linear tool magazine and disc tool magazine can greatly improve the processing efficiency and save labor costs for users. Moreover, ATC CNC machine can adapt to complex processing occasions and improve the quality of products. And the user doesn’t need to load and unload work pieces frequently. This machine has a wide range of applications in cabinet making, wooden door carving, screen carving, advertising sign engraving, home decoration, crafts, foam molding, metal engraving and many other fields.

What is Multi Head CNC Router?

Multi head CNC router has multi spindles. A multi head CNC router usually adopts 2 to 4 spindles and each spindle carries a cutting tool. The external cylinder controls the movement of the spindles, and the spindles work in turn to process the work pieces. Multi head CNC router is like a simple ATC CNC router. It automatically switches cutters by changing its spindles.

The multi spindles can realize seamless switching during the machining process. After a spindle finishes its work, it moves to the beam and the next spindle starts to work at the same time. Watch the video below to learn how a multi head CNC router switches spindles quickly. As you can see from the video, multi head CNC router changes cutters by changing spindles. In this way, multiple processes can be completed on one machine. It greatly improves the processing efficiency.

Multi head CNC router can process cabinets, wardrobes, beds, doors and shows higher efficiency and precision than ordinary CNC router that only adopts one spindle. It can also perform woodworking artwork carving, which is not possible to finish with an ordinary wood CNC router. Moreover, the machine integrates various processes into one process. It greatly avoids the bumps and damage to the work pieces caused by multiple manual loading and unloading processes. In addition, with the redundant spindles adopted, even if one spindle is broken, the machine can continue to work.